Customized High-Current PCIe 5.0 Case Study

Enabling reliable OCP power connector integration in high-density server environments

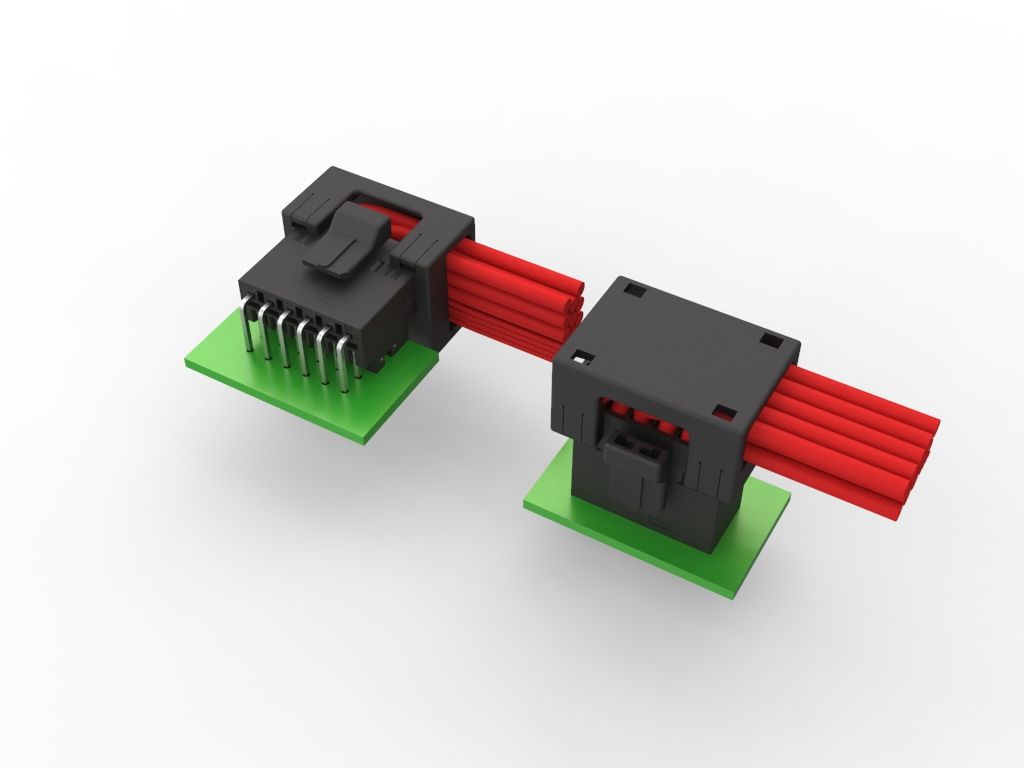

Tarng Yu Enterprise collaborated with a global server hardware manufacturer to develop a PCIe 5.0 / OCP power connector optimized for high-current applications. Through targeted engineering enhancements—including the addition of an integrated pull-tab design, optimization of cable exit height, and support for multiple cable routing orientations—the final solution enabled smoother system integration for the customer.

This design effectively addressed installation and maintenance challenges in highly space-constrained server architectures, helping the customer achieve stable deployment, improved serviceability, and increased overall installation and maintenance efficiency.

Project Background

Tarng Yu Enterprise specializes in high-current and high-density connector solutions for applications such as servers, industrial computers, AI accelerator modules, and embedded systems.

In next-generation server platforms, power modules and motherboard layouts are becoming increasingly compact. Traditional straight-exit power connectors often face mechanical constraints during installation and servicing, especially due to limited enclosure space and restricted cable bending angles. These limitations can negatively impact system integration efficiency and long-term reliability in real-world deployment scenarios.

To address these challenges, the customer required a next-generation power connector that meets the following criteria:

• Current capability of 7.6A to 14A per pin

• Compatibility with height-restricted server chassis

• Flexible cable exit orientations to support customized system routing

This project focused on achieving the optimal balance between electrical performance, mechanical space constraints, and long-term reliability.

Technical Specification Requirements

| Specification Item | Description |

|---|---|

| Pitch | 3.00 mm |

| Pin Configurations | 12P + 4S / 12P + 12S / 6P + 6S |

| Rated Current | 7.6A ~ 14A per pin |

| Wire Gauge | 18 ~ 14 AWG |

| Cable Exit Options | Straight / Side / 90° |

Engineering Solutions Developed by Tarng Yu

To overcome operational constraints encountered during installation and maintenance in high-density server enclosures, Tarng Yu implemented the following structural and mechanical optimizations:

● Integrated Pull-Tab Design to Improve Testing and Maintenance Efficiency

Reinforced Pull-Tab Structure for Faster Connector Removal

A strengthened pull-tab was added to allow technicians to quickly and safely remove the connector without the need to press retention latches or pull directly on cable bundles in confined spaces.

Key Benefits

- Simplified installation and removal: The pull-tab enables technicians to easily extract the connector even in limited or hard-to-reach areas, significantly reducing handling difficulty.

- Reduced risk of connector damage: Prevents excessive force on cables, minimizing the risk of damage to pins, conductors, or housings.

- Improved operational safety: Ergonomic pull-tab design reduces hand strain and potential injury during servicing.

- Enhanced maintenance and service efficiency: Allows rapid connector replacement during maintenance or troubleshooting, reducing system downtime and improving service turnaround time.

Side-Exit and 90° Cable Exit Designs to Meet System-Specific Routing Requirements

To address mechanical constraints and diverse system layouts, two alternative cable exit configurations were developed:

● Side-exit (horizontal) design, ideal for narrow or height-restricted spaces

● 90-degree vertical exit design, optimized for high-density motherboard layouts

Key Benefits

- Improved cable management and organization: Side-exit routing allows cables to be guided along the system structure, reducing clutter, tangling, and excessive bending.

- Reduced space occupation: Side-exit configurations lower the overall connector height, making them suitable for compact enclosures and space-optimized designs.

- Lower mechanical stress: By redirecting cables along natural routing paths, mechanical strain on pins and terminals is minimized, improving long-term connection reliability.

Project Results

The PCIe 5.0 / OCP high-current power connector developed in this project has been successfully deployed in the customer’s next-generation server platform. Through flexible cable exit configurations and an optimized pull-tab structure, the solution effectively addressed installation and maintenance challenges in high-density mechanical environments.

As a result, the customer achieved improved system integration efficiency, enhanced serviceability, and greater long-term operational reliability—supporting stable, scalable deployment in advanced server and computing systems.

- Tab Gallerys